Custom Side Gusset Bags

Get side gusset bags in premium quality and the best designs that allow you to protect the product with style. These bags have gussets that allow the expansion of the products without deteriorating the quality and structure of the packaging. We at Mylar Bags Maker manufacture the best quality bags keeping in mind the specific requirements of the products.

With the additional features and multiple layers, our brand enhances the functionality of your custom pouches. You can avail of free of cost design consultation for the printing of your custom shape gusset bags and get a promotional tool with minimal investment.

Packaging is one of the key concerns of a brand. The protection and presentation of the product and the market value of a brand heavily rely on the packaging. Side gusset bags can fulfill all these requirements of your brand and help you secure a significant amount of customers’ trust.

These bags are an excellent depiction of your brand’s creativity in using material wisely. The side gusset is an expandable feature in these bags that gives you more volume as compared to other types of pouches. Not only this when you pack the products, you get a stable structure of custom side gusset bags that can stand in an upright position or you can lay them flat easily.

Businesses prefer this style of mylars because these bags allow easy transportation and storage. Not only this, the durable and barrier properties of the bags give remarkable protection to the products inside the bags.

Applications Of Side Gusset Bags

Like other types of mylar bags, they are also used in multiple industries. You can give your product perfect protection by investing in these mylars as they have a non-porous surface that does not allow the exchange of gases and moisture. The common applications are:Food Industry

- Coffee and tea packaging

- Snacks and dry fruits

- Flour, sugar, and grains

- Pet food

- Powdered drink mixes

- Bakery items

Pharmaceutical And Healthcare

- Protein powders and dietary supplements

- Herbal medicines and medicinal powders

- Pharmaceutical chemical

Agriculture Sector

- Seeds and fertilizers

- Animal feed

- Pesticides and plant nutrients

Industrial Applications

- Chemical powders and granules

- Detergents and cleaning agents

- Hardware and small mechanical parts

Product Protection With gussets And Sturdy Material

This side gusset allows the bags to expand and maintain a stable shape, so when you pack products that naturally release gases such as freshly roasted coffee and some fermented products, this design of custom gusset bags provides extra volume so that the expanding components can get sufficient space without damaging the quality of the packaging.Expansion

When the product releases gases the bag can expand and give extra volume due to the presence of gussets. This prevents the irregular bulging and bursting of packaging.Structural Stability

In addition to giving additional space the gussets also have an additional purpose. Due to the gussets, the bags have structural integrity and can be placed in an upright condition. This makes the display and storage of products easy.Controlled Venting

Although gusset bag packaging is manufactured to allow the gases to escape, the material of the packaging is mainly designed to provide barrier properties. To allow the producing gases an escape, we add a one-way valve on the bags. This valve allows the gases to go out of the bag due to the internal pressure that allows the valves to open for gaseous exit, the external gases cannot enter the bags. We keep in mind all the concerns of our customers and make sure that their products remain of the perfect quality. Considering this, we are giving a one-way valve on custom holographic bags with a gusset. These valves help in the retention of product quality via the following reasons:Prevents Oxidation

Some of the products such as roasted coffee beans release carbon dioxide over time which allows the coffee to oxidise. So by using the valves, you can allow the gases to expel and make the release of gases easy.Prevents Bloating

When you pack coffee or fermented products, then one thing that you may have to face is the bloating of the packaging. This bloating can even cause your bags to explode. So to prevent this product damage gussets are an ideal option These bags are usually used as custom side gusset bags for food because foods are the main products that release gases. Apart from this, several other products can be packed as mentioned above. the style of the mylars, the material that we use is also excellent in quality allowing the retention of product quality. Apart from using BoPET material, we use the following materials to strengthen the mylars, such as:- Polyethylene (PE)

- Polypropylene

- Polyethylene Terephthalate

- Aluminum Foil

- Kraft Paper

- Metallized Films

- Nylon

- Ethylene Vinyl Alcohol

Manufacturing Process

In our custom side gusset bags wholesale services the manufacturing of the bags is done in several key processes that are interconnected to each other. Initially, the material is selected and undergoes several mechanical and chemical processes. We follow the below-mentioned steps:Raw Material Selection And Preparation

Based on the desired properties of the customers we select the material. If you need high-end barrier properties then we give PET and aluminum foil combination. On the other hand, if the customers are looking for a recyclable option then we use kraft with BoPET. The polyethylene terephthalate is prepared in pellet form and then melted to biaxially extrude the film. After this, we use other materials such as aluminum foil, and layer them with Polyethylene terephthalate to create multi-layer packaging. Sometimes kraft material is also used to create a natural look of the packaging.Film Extrusion And Lamination

The plastic materials are melted to form a thin layer. After this multiple layers are bonded together to achieve specific properties such as moisture resistance, prevention of oxidation, etc. The lamination layers undergo a curing process in which the layers bond together properly.Common Printing Techniques Used For Side Gusset Bags

Several printing techniques are employed when creating designs for gusseted bags for food. Each method has its strengths and weaknesses, making them suitable for different applications.Flexographic Printing

It is one of the common options used for the printing of mylar as it has high speed and efficacy. We use flexible relief plates to transfer the ink at high speed on the material. This method is quite cost-effective and is suitable for various types of inks and materials. Not only this, flexography has a fast drying time which is why it rapidly produces custom side gusset bags bulk. The quality of the design can vary sometimes depending highly on the material on which printing is being done.Rotogravure Printing

Rotogravure printing gives premium-quality images and is capable of printing intricate designs while maintaining quality across the manufacturing process. We do not prefer this method for short runs however, for long runs, it is an ideal option.Digital Printing

For short runs, digital printing is our preferred option. This is because in this method no setup is required. Apart from this it has high speed and gives perfect quality. In the long run, it is not useful as the cost per unit of the materials may increase.Coatings For Enhanced Application

To enhance the durability and functionality of the packaging we use different types of coatings. These coatings improve the barrier properties and protect custom gusset food bags from damage. These coatings include the following:- Polyethylene (PE) Coatings

- Silicone Coatings

- PVDC (Polyvinylidene Chloride) Coatings

- Acrylic Coatings

- Wax Coatings

Additional Features Used On Mylar Bags

Sometimes your product needs some of the additional features that can help in easy handling. For instance, custom spout pouches are used to pack liquids so that one can easily pour the contents inside the bags. Some other add-ons that we use are as follows:- Zippers and resealable closures

- Degassing valves

- Tear notches

- Hang holes

- Transparent windows

Adhesives

To assemble the bags or for multiple-layer bottom gusset bags we use different types of laminated films. These adhesives firmly bind the multiple layers and enhance the barrier-based properties of the mylar pouches. We have different types of adhesives, each having a different quality:- Solvent-based adhesives provide high-end barrier properties.

- Water-based adhesives are a sustainable option and are lightweight.

- Hot melt adhesives are applied to seal the bags as they instantly bond together.

- UV-curable adhesives ensure strong adhesion and quick curing of the gum when UV light is applied.

Call Us Now!

For custom side gusset bags near me, get in touch with Mylar Bags Maker and avail the best design and premium quality bags at affordable rates. We manufacture one of the finest quality packaging boxes that keep your packed products in perfect condition. So call us now or fill in the quote to receive your order in a few days!| Style | Custom Side Gusset Bags |

| Dimension (L + W + H) | All Custom Sizes & Unique Shapes |

| Quantities | Minimum Order Quantity is 500 Pieces |

| Paper Stock | BoPET (biaxially-oriented polyethylene terephthalate) film, 89 µ to 178 µ (or 3.5 mils up to 7 mils) |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Scored, Perforation |

| Additional Options | Zipper, Hanging holes, Tear Notch, stand-up feature, child-resistant lock |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 14-22 Business Days |

| Shipping | FLAT |

Specifications

Clear

Recyclable Mylar

Kraft

Standard Mylar

Metallic

PCR Mylar

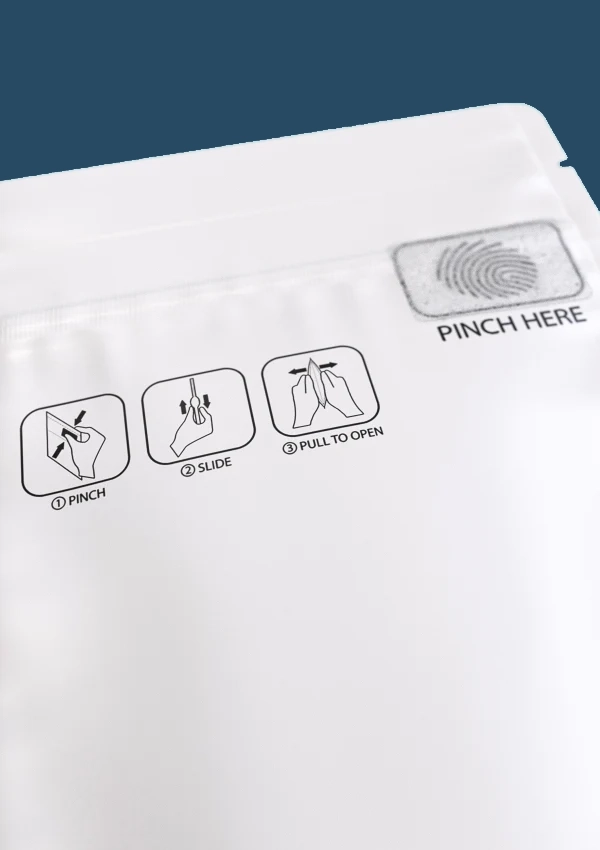

Pinch N Slide

Child-resistant closure mechanism that involves sliding bag open from the corners.

Pinch N Pull

Child-resistant closure mechanism that involves pulling the bag open from a specific spot.

Standard

For when child-resistance is not needed.

Raised Spot Gloss

Spot Gloss

Window

Custom Die-Cut

Faux Foils

Soft Touch

Holographic

Other

Gusset

Tear Notch

Hang Hole

Rounded Corners

See Our Clients' Experiences

Client's Frequently Asked Questions

Have questions? Read our most frequently asked questions and get all your queries answered by professionals. If you need any additional assistance then you can contact our customer care department.