Custom Flat Pouches

Materials Used In Flat Pouches

The material used in the manufacturing of flat bags is BoPET. Apart from this material, we use polyethylene, polypropylene, and polyterephthalate to manufacture flat pouches. These materials have the following qualities due to which we prefer them in the manufacturing of custom shaped mylar bags:- Flexibility

- Lightweight

- Good moisture resistance

- High clarity and heat resistance

- Strength and durability

- Oxygen resistance

- Chemical resistance

Multi-Layer Laminates

If you are looking for premium quality packaging material and want to take the protection of your products to the next level, then get flat barrier pouches made with multiple layers. In it, we use PET along with aluminum foil to enhance the protective ability of the bags.Thickness Variations

We give our customers the complete authority to select the packaging as per their product requirements and duration of use. Some of the common thicknesses that we give are as follows:- 2.5 mil is a good option when you have to use the bag for temporary purposes

- 3.5 mil mylar bags have medium thicknesses that are resistant to punctures.

- 5 mil custom printed flat pouches are a perfect option to pack food as they have high barrier properties.

- 7 to 10 mil are heavy-duty bags that are used for bulk and long-term storage.

Best Printing Methods For Flat Pouches

If you want to give an appealing look to the product,then you must opt for printing options. For custom printed lay flat pouches, we have several options that play a crucial role in the promotion of your brand. The most suitable methods of printing are as follows:Flexographic Printing

Flexography is an ideal method that produces high-quality prints with the help of flexible printing plates. It is a cost-effective process that gives high volumes in a short duration.Rotogravure Printing

In the rotograuve printing process for printed lay-flat pouches, we use large cylindrical plates that transfer the ink to the surface of the paper. This is a perfect option for intricate designs and large-scale production when you need consistent quality and designs. Digital Printing Digital printing allows for the quickest turnout, as here, there is no set-up cost. This is perfect for small-scale production of custom mylar bags. Digital printing is also an environmental method because, in this, there is minimal use of ink. The two methods that we do not recommend to our customers for mylar lay flat pouches are as follows:Screen Printing

This method is not ideal for flexible packaging because the application of ink can be uneven. This method is limited to color gradients and fine details.Offset Printing

Offset printing is designed for rigid surfaces such as paper and cardboard. When used on mylar material, the color quality declines due to poor adhesion.Chemicals Used In Manufacturing Flat Pouches

To enhance the properties of custom printed flat pouches, various chemicals are used. The common chemicals that we use include adhesives such as polyurethane-based adhesives that bond multiple layers together. Apart from this, we apply different coatings onto the material that enhances the durability and barrier properties of the bags. Lastly, we have to use different ink based on the requirements of your brand. Our ink is UV curable and solved, which ensures the longevity of the designs and resists fading.Add-Ons For Flat Pouches

To enhance the functional properties of the mylar bag, different add-ons are used. Such as zippers are used to give mylar ziplock bags, and the spot is added for liquid packaging to get spout mylar bags for easy pouring. You can also opt for tear notches and press-to-close options to make your bags more functional and easy to use.Call Us Now!

Get your brand’s custom flat pouches and give your products an excellent level of protection. We at Mylar Bags Maker are helping all our clients with the best deals and discounts without compromising the quality of our bags. So call us now and get your packaging in a minimum time duration.| Box Style | Custom Flat Pouches |

| Dimension (L + W + H) | All Custom Sizes & Unique Shapes |

| Quantities | Minimum Order Quantity is 500 Pieces |

| Paper Stock | BoPET (biaxially-oriented polyethylene terephthalate) film, 89 µ to 178 µ (or 3.5 mils up to 7 mils) |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Scored, Perforation |

| Additional Options | Zipper, Hanging holes, Tear Notch, stand-up feature, child-resistant lock |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 14-22 Business Days |

| Shipping | FLAT |

Specifications

Clear

Recyclable Mylar

Kraft

Standard Mylar

Metallic

PCR Mylar

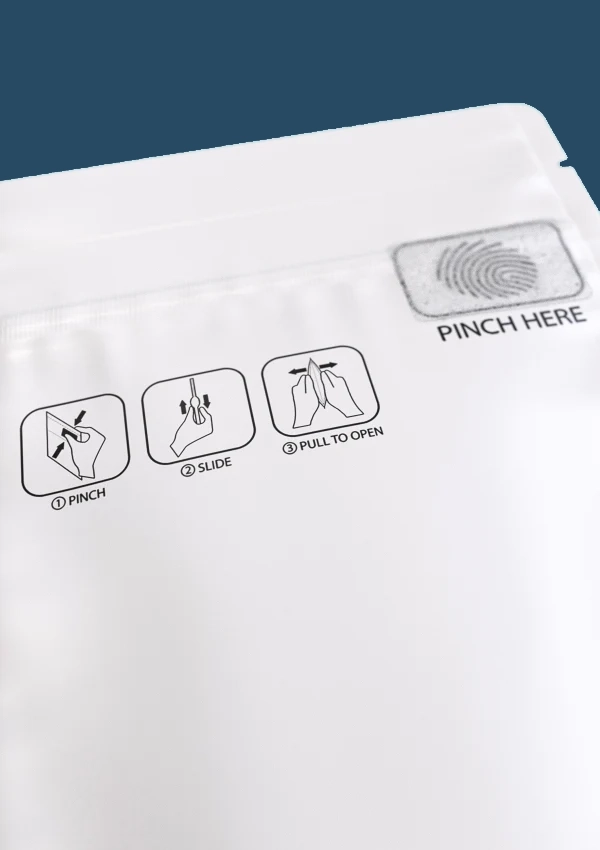

Pinch N Slide

Child-resistant closure mechanism that involves sliding bag open from the corners.

Pinch N Pull

Child-resistant closure mechanism that involves pulling the bag open from a specific spot.

Standard

For when child-resistance is not needed.

Raised Spot Gloss

Spot Gloss

Window

Custom Die-Cut

Faux Foils

Soft Touch

Holographic

Other

Gusset

Tear Notch

Hang Hole

Rounded Corners

See Our Clients' Experiences

Client's Frequently Asked Questions

Have questions? Read our most frequently asked questions and get all your queries answered by professionals. If you need any additional assistance then you can contact our customer care department.

Yes, we also have the option of recyclable flat pouches. The single-layer pouches are recyclable, while multilayer pouches are not.

Though these pouches are manufactured mainly for dry product packaging, you can use them for liquid packaging, for which we apply special coatings.

Yes, especially if you select the option of aluminum-lined pouches.

Yes, we give double-sided printing too.

If you have selected mylar or plastic material, then you can use them in the microwave. Aluminum foils must never be used in the microwave.